Sigray Unveils the Apex-Hybrid: A Breakthrough 3D X-Ray System for Failure Analysis (FA) and Electronics Reverse Engineering

System Delivers Industry-Leading 350nm High-Resolution Imaging and Two-in-One Capabilities (Laminography and Tomography)

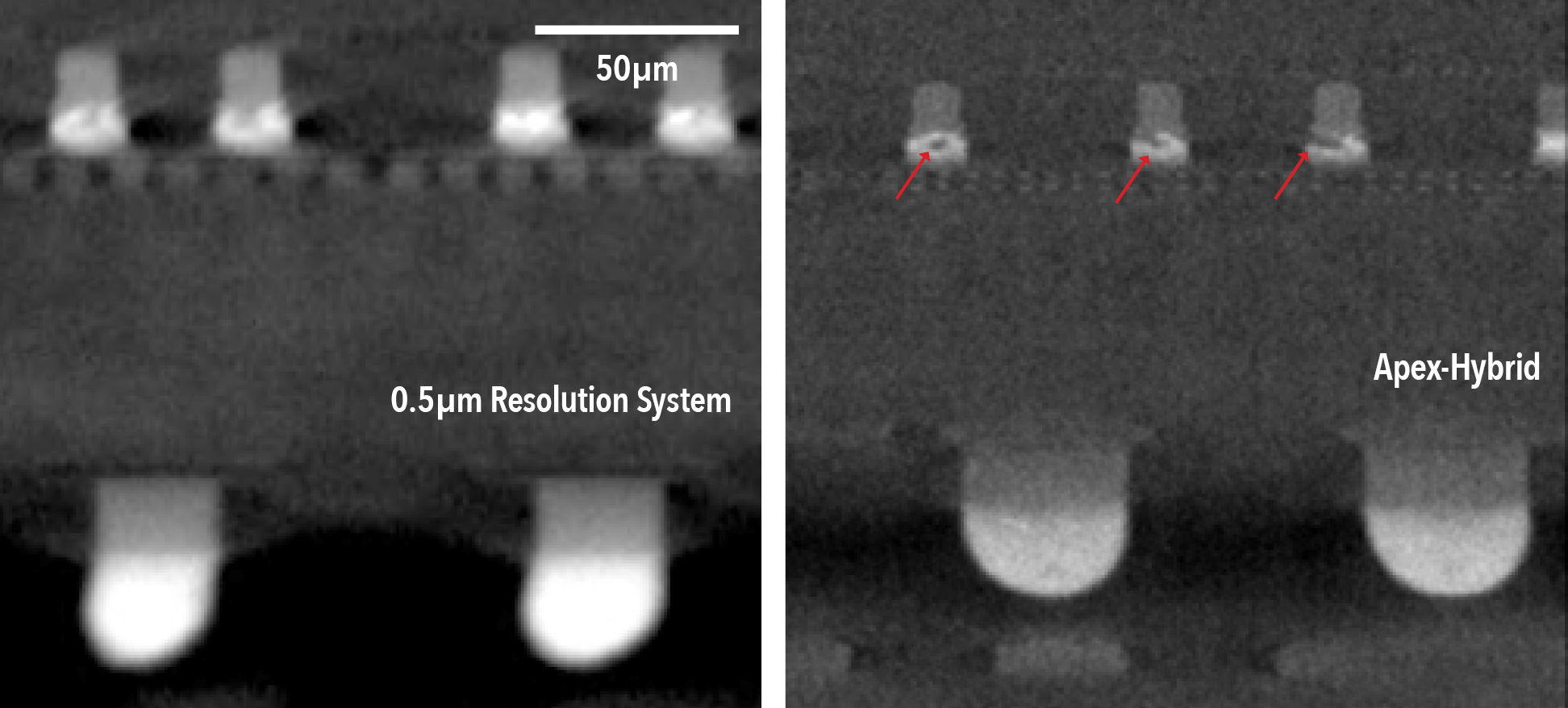

BENICIA, CALIFORNIA / ACCESS Newswire / April 21, 2025 /Sigray, Inc., a pioneer in X-ray microscopy, proudly announces the launch of the Apex-Hybrid-a cutting-edge system developed to transform failure analysis (FA) workflows in semiconductor and electronics laboratories. With interchangeable laminography and tomography modes and outstanding 100nm pixel resolution (350nm spatial resolution), the Apex-Hybrid delivers high-resolution imaging for both large packages and PCBs, as well as smaller, intricate components-all with exceptional speed and efficiency.

The Apex-Hybrid system represents a breakthrough in imaging technology, delivering high resolution and image quality for failure analysis and reverse engineering.

Engineered to meet the rapidly evolving demands of semiconductor failure analysis, the Apex-Hybrid addresses the critical need for higher resolution to identify defects in both advanced packaging and larger, intact assemblies. This demand is fueled by industry trends such as heterogeneous integration and wafer-level packaging.

The Apex-Hybrid overcomes the fundamental challenges of traditional imaging approaches:

Conventional CT often struggles with beam hardening artifacts and long acquisition times when imaging large samples.

Traditional CL is plagued by laminographic artifacts, particularly in vertical cross-sectional views, which can severely degrade image quality.

"The Apex-Hybrid provides a long-overdue solution for comprehensive X-ray imaging across size scales in failure analysis," said Dr. Wenbing Yun, CEO & CTO of Sigray, Inc. "It gives engineers the ability to resolve submicron defects at outstanding 350nm spatial resolution in microbumps and TSVs in both full-scale 300mm wafers and miniaturized chiplets-without compromise."

Applications in Failure Analysis and Reverse Engineering

Sigray 's Apex-Hybrid technology has seen strong demand from both major semiconductor failure analysis teams and reverse engineering researchers, thanks to its industry-leading 350nm spatial resolution.

One of the first academic installations of the Apex-Hybrid system is at the University of Florida (UFL) with Prof. Navid Asadi Zanjani. The system is housed in Dr. Asadi 's SCAN Lab, a $15M facility dedicated to defect detection, failure analysis, and hardware security. At UFL, Apex-Hybrid is being applied to both defect inspection and counterfeit electronics detection-critical and growing challenges in today 's era of heterogeneous integration and 3D packaging, where defect sizes are shrinking and hardware trojans are becoming increasingly elusive.

"We 're excited to be among the first to install the Apex-Hybrid system," said Prof. Asadi. "The complexity of defect detection and ensuring the physical security of electronics is intensifying, especially with the rise of advanced packaging techniques and the chiplet ecosystem, where multiple components from different manufacturers are integrated into a single device. As feature sizes continue to scale down, high-resolution 3D x-ray imaging-like what Apex-Hybrid provides-will be essential."

He added, "I 'm also looking forward to our collaboration with Sigray in applying Artificial Intelligence to develop a fully autonomous framework for reverse engineering and malicious hardware detection."

Advantages for Comprehensive Failure Analysis

The Apex-Hybrid introduces a novel workflow for failure analysis, enabling users to image large, intact samples-such as boards and wafers-at 350nm resolution using its laminography mode. This allows for efficient identification of a region of interest (ROI), which can then be cut out and imaged in artifact-free tomography modefor high-resolution inspection. This final step enhances defect analysis by providing precise detail on features such as shape and size.

Key advantages of Apex-Hybrid 's interchangeable modalities include:

Two-in-one system: Traditionally, separate laminography and tomography systems were required. Apex-Hybrid combines both into one system via a patent-pending changeable beamline-reducing cost and saving lab space.

High imaging speed:Achieve fast 3D X-ray scans within minutes, maximizing throughput.

Automation: Integrated robotic handling enables batch processing of up to ten 100 × 100 mm samples, allowing unattended operation overnight and on weekends.

Cost-effective:A long-lifetime X-ray source keeps operational expenses low.

For more information, visit www.sigray.com/apex-hybrid or contact info@sigray.com. Sigray provides complimentary demonstrations of its products on customer samples for purchasing evaluation.

About Sigray, Inc.

Sigray, Inc. designs and manufactures state-of-the-art X-ray microscopy and microanalytical solutions that redefine standards in resolution, speed, and versatility. Specializing in failure analysis, semiconductor metrology, and materials research, Sigray 's technologies help industries drive innovation, enhance quality control, and improve product reliability.

Contact Information

SH Lau

Vice President, Business Development

shlau@sigray.com

408-505-2139

SOURCE: Sigray

View the original press release on ACCESS Newswire

© 2025 ACCESS Newswire. All Rights Reserved.